3D printing has revolutionized the way we create and manufacture objects. However, like any technology, it comes with its own set of challenges. In this article, we will explore 3D printing troubleshooting: 15 most common problems & solutions to help you navigate these issues effectively.

1. Poor Adhesion to the Build Plate

One of the most frequent issues encountered in 3D printing is poor adhesion. This can lead to warping and failed prints. To improve adhesion, ensure that your build plate is clean and leveled. You might also consider using adhesives like glue sticks or specialized sprays.

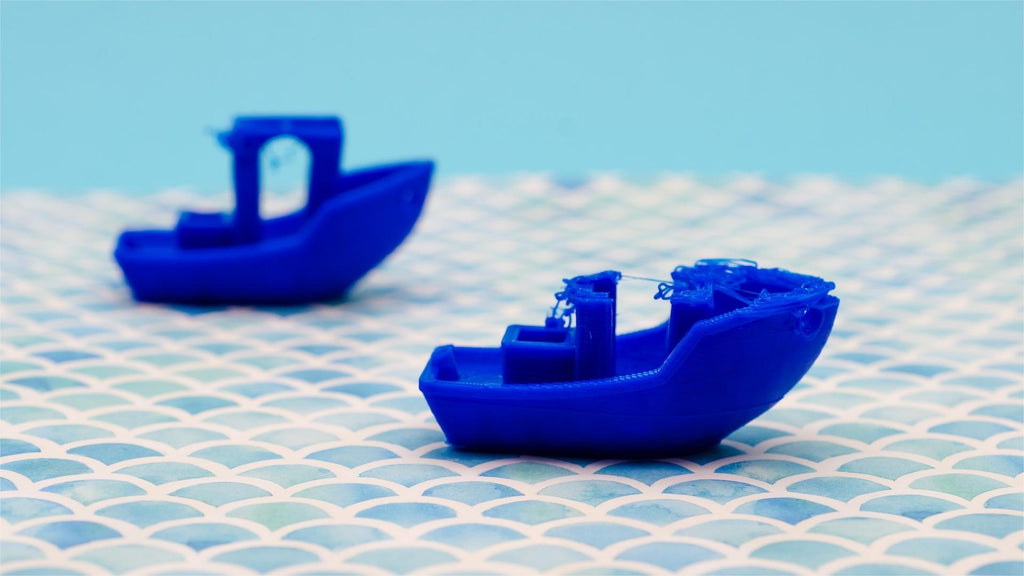

2. Stringing and Oozing

Stringing occurs when filament oozes out of the nozzle during travel moves. This can be minimized by adjusting the retraction settings in your slicer. Increasing the retraction distance and speed can significantly reduce this issue.

3. Layer Separation

Layer separation can happen when the layers of a print do not bond properly. This often results from insufficient temperature or incorrect print speed. Ensure that your nozzle temperature is set correctly for the filament you are using.

4. Under-extrusion

Under-extrusion leads to gaps in your print. This can be caused by a clogged nozzle or incorrect filament diameter settings. Regularly check your nozzle for clogs and calibrate your extruder steps per millimeter.

5. Over-extrusion

Conversely, over-extrusion can create blobs and uneven surfaces. This issue can be resolved by adjusting the flow rate in your slicer settings. Reducing the flow rate by 5-10% can often yield better results.

6. Warping

Warping is a common problem, especially with ABS filament. To combat this, consider using a heated bed and ensuring that the first layer adheres well. Additionally, using an enclosure can help maintain a stable temperature.

7. Nozzle Clogs

Nozzle clogs can halt your printing process. Regular maintenance, such as cleaning the nozzle and using high-quality filament, can prevent this issue. If a clog occurs, you may need to perform a cold pull to clear it.

8. Filament Jamming

Filament jams can occur due to improper feeding or a misaligned extruder. Ensure that your filament path is clear and that the spool is unwinding smoothly. If jams persist, check the extruder tension.

9. Inconsistent Extrusion

Inconsistent extrusion can lead to uneven prints. This can be caused by variations in filament diameter or issues with the extruder. Regularly calibrate your printer and use high-quality filament to minimize this problem.

10. Print Quality Issues

Print quality can be affected by various factors, including temperature fluctuations and mechanical issues. Regularly check your printer's components and maintain a consistent environment for optimal results.

11. Layer Misalignment

Layer misalignment can occur due to mechanical issues or incorrect settings. Ensure that your printer is properly calibrated and that the belts are tight and free of debris.

12. Electrical Issues

Electrical problems can lead to unexpected shutdowns or erratic behavior. Regularly inspect your wiring and connections to ensure everything is functioning correctly.

13. Software Errors

Software errors can arise from outdated firmware or slicer settings. Always keep your software updated and double-check your slicer settings before printing.

14. Filament Quality

The quality of your filament can greatly affect your prints. Always opt for reputable brands and store your filament properly to prevent moisture absorption.

15. Calibration Problems

Calibration is crucial for successful 3D printing. Regularly calibrate your printer, including the bed leveling and extruder steps, to ensure optimal performance.

For a more comprehensive guide on 3D printing troubleshooting: 15 most common problems & solutions, visit .

By understanding these common issues and their solutions, you can enhance your 3D printing experience and achieve better results. Remember, troubleshooting is a part of the learning process, and with practice, you will become more adept at resolving these challenges.